YX65 Bemo style standing seam roofing machine

Straight sheet Standing Seam Roof Machine standing seam roofing machine YX65 Standing seam machine

standing seam curving machine bemo style standing seam bending machine

Manual Curving machine for YX25/38 Standing seam roof panel Bending machine

960 Color Steel Tile Roof Machine

Double layer roof panel machine duplex roof machine roof panel machine standing seam roofing machine

YX19-76 Roll Shutter Door Roll Forming Machine

Floor Deck Forming Machine metal floor decking machine

Down Pipe Roll Forming Machine

YX830 Metal Roofing Panel Machine

YX51-820 Steel Roof Forming Machine

Color Roof Tile Forming Machine

Step tile roof panel machine glazed tile forming machine roofing panel machine roof panel machine

YX19-75-825 Corrugated roof panel machine Corrugated sheet making machine

Aluminum Corrugated & Wave Roofing Forming Machine

Color Steel Roof Forming Machine wave sheet making machine Corrugated sheet making machine

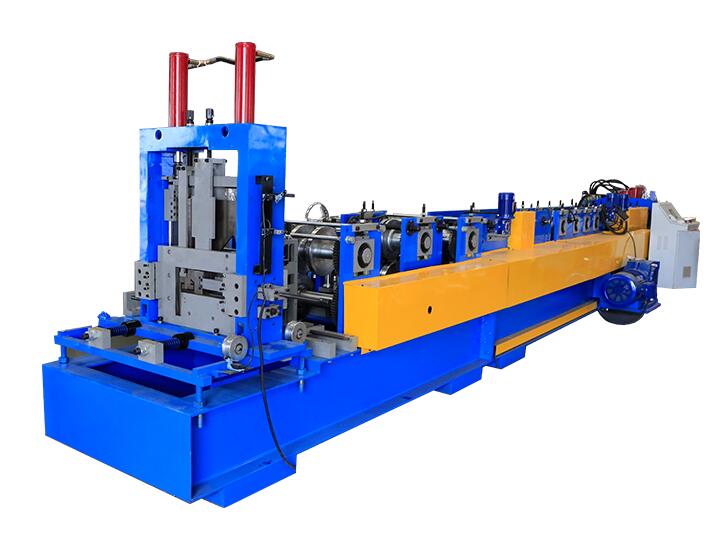

C80-300/Z120-300 purlin interchangeable roll forming machine

Z Purlin Forming Machine With Post-cutting

Z Purlin Forming Machine With Pre-punching

C60-250 Automatic purline machine purline making machine C purline forming machine

echnology parameters

※The weight of the Machine :9T

The total dimension of machine: (length)10m x (width)1.4m x (height)1.8m。

1)Decoiler

l Decoiler Type : manual decoiler

l weight capacity of decoiler : 5.0T

2)Feeding and Leveling Device

It used for making the material flat before feeding into the roll forming machine

3)Rolling Forming System

l main motor type : phase asynchronous motor(manufacturer: shanghai nanyang)

l motor power: 15KW

l speed of forming : 10-14.8m/min

l material of roller : GCr15

l 18 groups rollers

l material of main shaft : 40Cr(The main shaft have the high frequency grinding &heat Treatment and the surface of shaft is chroming)

l diameter of main shaft: ø70mm

4)Hydraulic Punching & Cutting (punching and cutting are after roll forming)

l Punching Type: Hydraulic Punching

l Cutting type: Hydraulic cutting (C80-250/Z120-250 use a specification shearing tool and C80-300/Z120-300 use a specification shearing tool.we have the patent technology.)

l Cutting material: Cr12 Cr12MoV Cr12(total three blades)

l Hydraulic power: 5.5KW

l Hydraulic Pressure: 16Mpa

5) PLC Control System

l Control the quantity &punching length& cutting length automatically

l Voltage: 380V, 3 Phase 50Hz

l Size of PLC Control Board: 700mm(L)x1000mm(H)x300mm(W)

l PLC manufacturer: Japan Panasonic

l Solenoid valve: Beijing hade

l Oil hydraulic cylinder: longyuan

l Oil pipeline: parkers

l Touch Screen(manufacturer: Japan Panasonic)

l Encoder : Schneider(france)

6)Product support frame

The length of product support frame : 6m