YX65 Bemo style standing seam roofing machine

Straight sheet Standing Seam Roof Machine standing seam roofing machine YX65 Standing seam machine

standing seam curving machine bemo style standing seam bending machine

Manual Curving machine for YX25/38 Standing seam roof panel Bending machine

960 Color Steel Tile Roof Machine

Double layer roof panel machine duplex roof machine roof panel machine standing seam roofing machine

YX19-76 Roll Shutter Door Roll Forming Machine

Floor Deck Forming Machine metal floor decking machine

Down Pipe Roll Forming Machine

YX830 Metal Roofing Panel Machine

YX51-820 Steel Roof Forming Machine

Color Roof Tile Forming Machine

Step tile roof panel machine glazed tile forming machine roofing panel machine roof panel machine

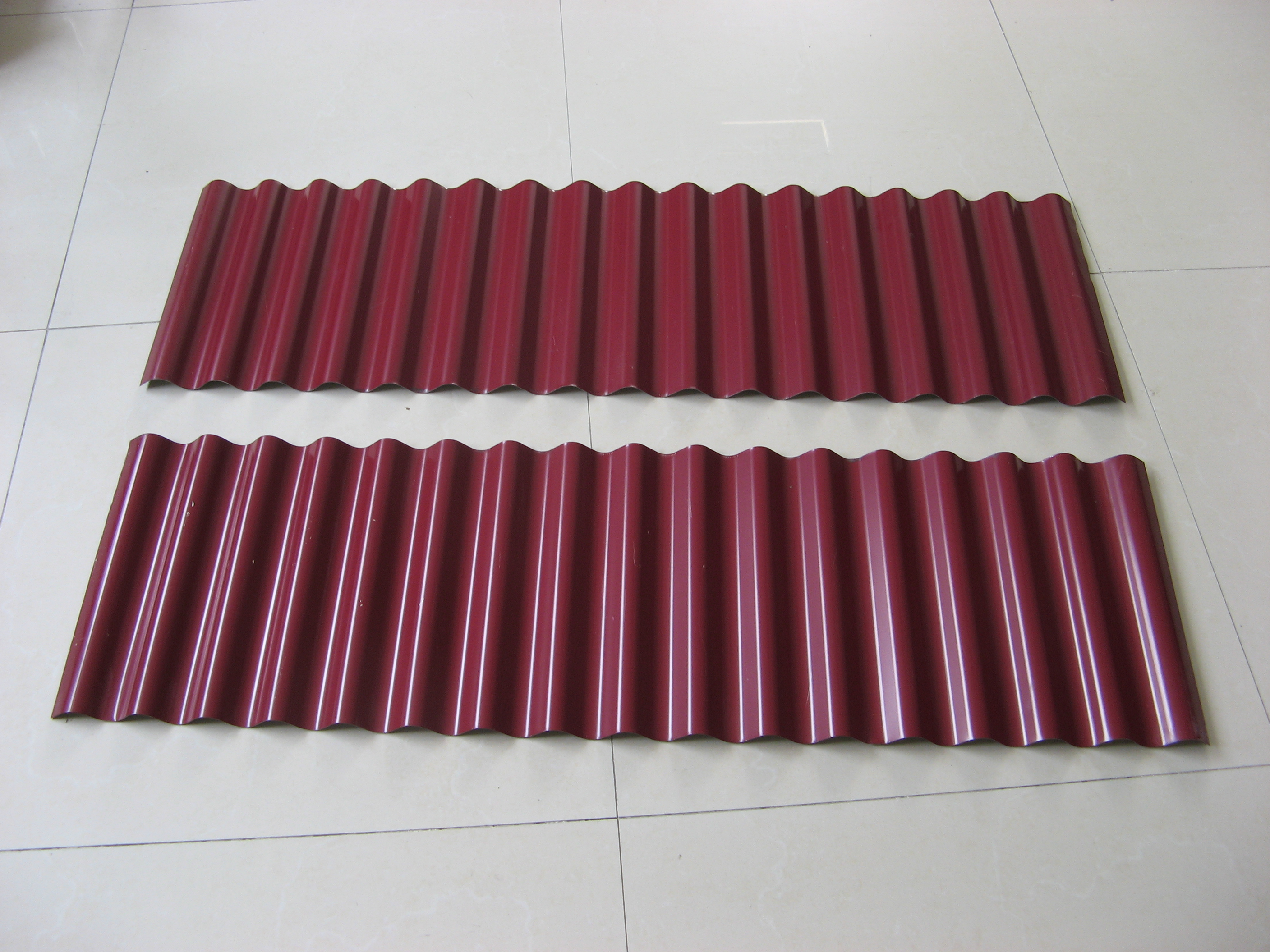

YX19-75-825 Corrugated roof panel machine Corrugated sheet making machine

Aluminum Corrugated & Wave Roofing Forming Machine

Color Steel Roof Forming Machine wave sheet making machine Corrugated sheet making machine

C80-300/Z120-300 purlin interchangeable roll forming machine

Z Purlin Forming Machine With Post-cutting

Z Purlin Forming Machine With Pre-punching

C60-250 Automatic purline machine purline making machine C purline forming machine

Model

Corrugated Sheet making Machine,can do as customer's design

Product Description

This YX19-75-825 Corrugated Sheet Forming Machine is suitable for forming 0.3-0.7mm thickness PPGI and galvanized sheet. Beautiful sample and high producing speed. It is very difficult to form PPGI material thickness smaller than 0.25mm, we are successful to solve this problem and become ahead of this design.

The product produced by these series machine is used for roof or wall in building. With this product for roof and wall, it is with the advantage of lower cost, soon fixture and uneasy damaged, this series product is suitable for steel structure factory, store and public big building. It is common used in different fields.

Main Technical Parameters

| Technical Parameter | Description |

| Material Thickness | 0.3-0.8mm |

| Material Width | 1000mm |

| Effective Width | 825mm |

| Shaft diameter | φ75mm |

| Manufacture material | 40Cr for rollers, H-Beam for frames |

| Forming Station | 20 steps |

| Producing speed | 10-20m/min |

| Motor power | 7.5Kw |

| Weight | 6000KG |

Hydraulic cutting device

Pump motor =3KW; Cutting pressure=Max.8Mpa

Cutting tool material: Cr12, Heat treatment

PLC Control System

Control the cutting length & quantity automatically.

Combined with:PLC, inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±3 mm

Control voltage 24V

Whole Producing Line Components

1)5tons decoiler

2)Roll forming machine

3)Hydraulic cutting device

4)Product rack for collecting products

5)PLC control box

Profile design drawing or base on customer's requirement

Machine and sample details