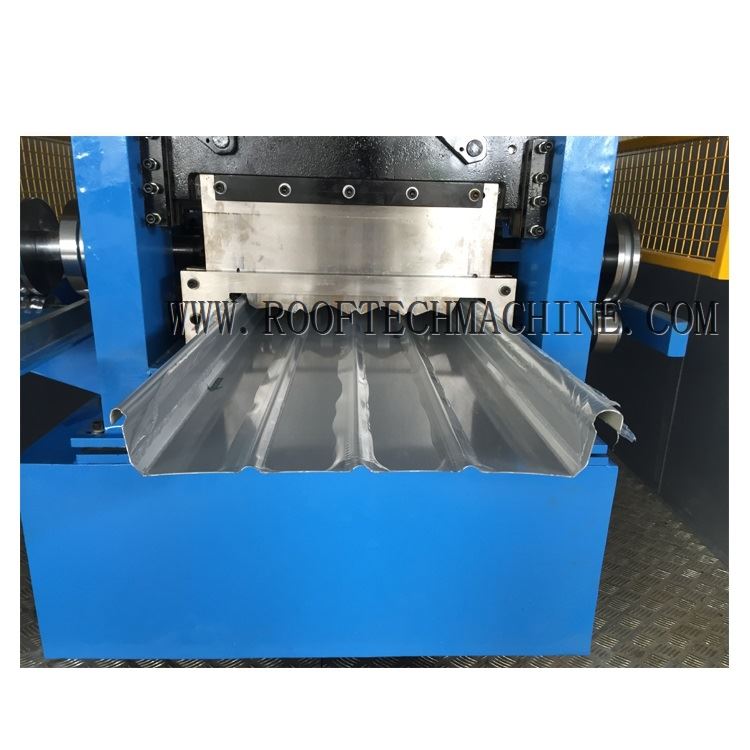

YX65 Bemo style standing seam roofing machine

Straight sheet Standing Seam Roof Machine standing seam roofing machine YX65 Standing seam machine

standing seam curving machine bemo style standing seam bending machine

Manual Curving machine for YX25/38 Standing seam roof panel Bending machine

960 Color Steel Tile Roof Machine

Double layer roof panel machine duplex roof machine roof panel machine standing seam roofing machine

YX19-76 Roll Shutter Door Roll Forming Machine

Floor Deck Forming Machine metal floor decking machine

Down Pipe Roll Forming Machine

YX830 Metal Roofing Panel Machine

YX51-820 Steel Roof Forming Machine

Color Roof Tile Forming Machine

Step tile roof panel machine glazed tile forming machine roofing panel machine roof panel machine

YX19-75-825 Corrugated roof panel machine Corrugated sheet making machine

Aluminum Corrugated & Wave Roofing Forming Machine

Color Steel Roof Forming Machine wave sheet making machine Corrugated sheet making machine

C80-300/Z120-300 purlin interchangeable roll forming machine

Z Purlin Forming Machine With Post-cutting

Z Purlin Forming Machine With Pre-punching

C60-250 Automatic purline machine purline making machine C purline forming machine

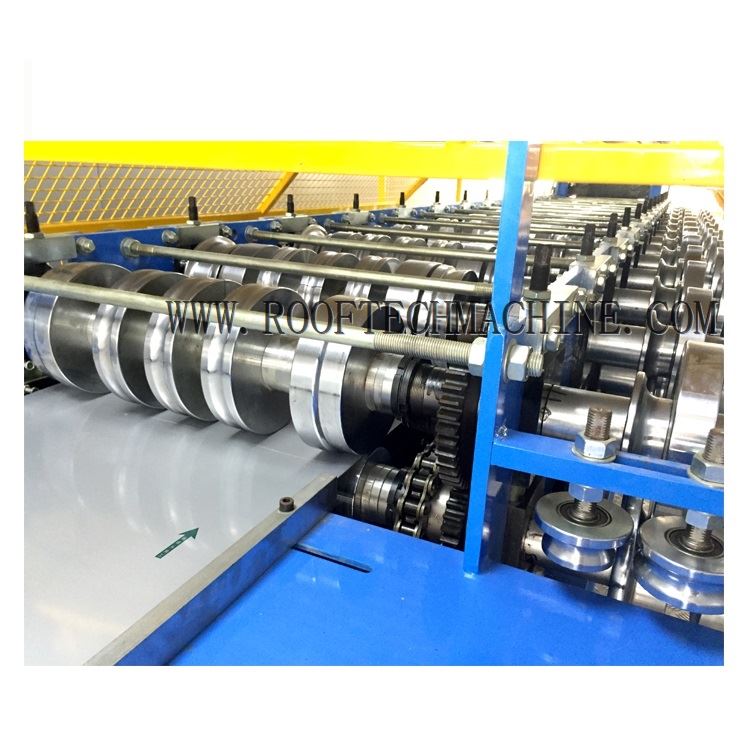

Main Technic Parameter:

| Size | 5800*1700*1500mm |

| Weight | 7000KGS |

| Voltage | 380V/50HZ/3PH |

| Motor Power | 7.5KW*2 sets |

| Hydraulic Power | 2.2KW |

| Forming Steps | 13 |

| Working Speed | 8-14m/min |

| Height of Roofing | 65mm |

| Effective Width | 400mm,425mm |

| Feeding Material Width | 575-578mm,600-603mm |

| Thickness for Aluminum Sheet | 0.8-1.2mm |

| Thickness for Steel | 0.6-1.0mm |

| Min. Width of tapered roofing | 250mm |

| Min.Length of tapered roofing | 1000mm |

| Cutting,Forming Tolerance | ±2mm |

| Roller material | High grade 45# forged steel, Plated hard chrome and polished all the rollers |

| Material of shaft | High grade 45# forged steel |

| Sprocket wheel | 45 steel high-frequencies quench |

| Cut-off system | Hydraulic cutting device |

| Material for Blade | Cr12 mold steel with quenched treatment 60-62°C |

| Material for frame of machine | Fine welded structural steel; |

| Material for producing roofing | Aluminum Sheet,PPGI Steel and G.I. Steel |

| Painted Color | Customization |

Main Accessories:

| (1) Main Forming Machine for making Straigt and Tapered Standing Seam Roofing; |

| (2) 5 Tons*600mm Uncoiler ; |

| (3) Leveler closed to feeding position (7 Rollers); |

| (4) Hydraulic System; |

| (5) PLC Computer Controlling System With Touch Screen ( Brand:Schneider ); |

| (6) Hydraulic Forming Cutter(2 sets cutters,one set for YX65-400,one set for YX65-425); |

| (7) Device for making tapered standing seam roofing; |

| (8) Safety Cover; |

| (9) Auto Seamer (2 set, Voltage: 220V/50HZ/1PH, 3 Steps for seaming straight roofing sheet); |

| (10) Hand Seamer(3 PCS); |

| (11) Run out tables(3 PCS); |

| (12) Tools; |

| (13) Operation Manual. |