YX65 Bemo style standing seam roofing machine

Straight sheet Standing Seam Roof Machine standing seam roofing machine YX65 Standing seam machine

standing seam curving machine bemo style standing seam bending machine

Manual Curving machine for YX25/38 Standing seam roof panel Bending machine

960 Color Steel Tile Roof Machine

Double layer roof panel machine duplex roof machine roof panel machine standing seam roofing machine

YX19-76 Roll Shutter Door Roll Forming Machine

Floor Deck Forming Machine metal floor decking machine

Down Pipe Roll Forming Machine

YX830 Metal Roofing Panel Machine

YX51-820 Steel Roof Forming Machine

Color Roof Tile Forming Machine

Step tile roof panel machine glazed tile forming machine roofing panel machine roof panel machine

YX19-75-825 Corrugated roof panel machine Corrugated sheet making machine

Aluminum Corrugated & Wave Roofing Forming Machine

Color Steel Roof Forming Machine wave sheet making machine Corrugated sheet making machine

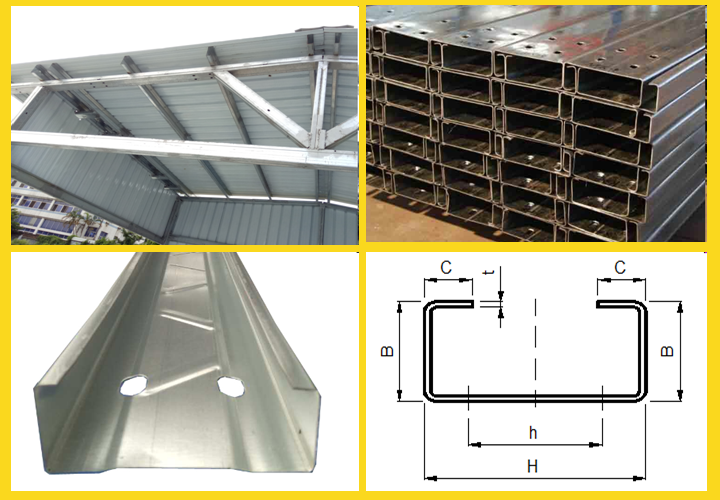

C80-300/Z120-300 purlin interchangeable roll forming machine

Z Purlin Forming Machine With Post-cutting

Z Purlin Forming Machine With Pre-punching

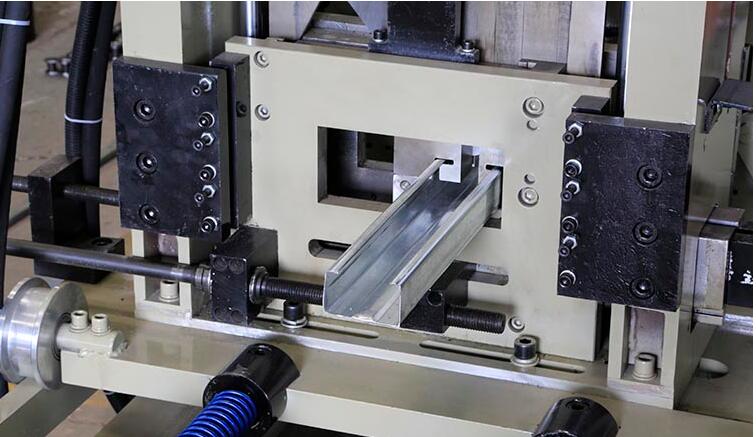

C60-250 Automatic purline machine purline making machine C purline forming machine

Our Machine Advantage

1.Good quality: We have a professional designer and experienced engineer team.And

the raw material and accessories we use are good.

2.Good service: we provide the technical support for whole life of our machines.

3.Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4.Easy operation:All machine cotrolling by PLC computer controlling systerm.

5.Elegant apperance:Protect the machine from rust and the painted colour can be customized

6.Reasonable price:We offer the best price in our industry.

Our Machine Technical Parameter

| No. | Item | parameter |

| 1 | Machine size | 9100*1700*1500mm |

| 2 | Machine weight | 7000kg |

| 3 | Machine power | 15kw |

| 4 | Hydraulic engine | 7.5kw |

| 5 | Roll speed | 30-35M/Min |

| 6 | Roll stations | 16 |

| 7 | Roller material |

Cr12Mov |

| 8 | Effective width | 60-250mm |

| 9 | Feeding width | / |

| 10 | Voltage | 380V 50Hz 3PH/Customized |

| 11 | Material thickness | 0.8-2.2mm/Customized |

| 12 | Control System | Schneider/Delta/Customized |

Our Machine Main Accesories